A na-etinye ọkpọkọ ọkpọkọ aka uwe seramiiki etinyere na ụlọ ọrụ Ngwuputa

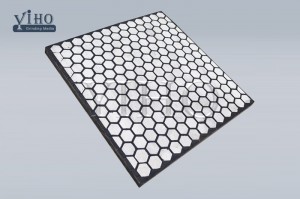

Ihe gbasara ọkpọkọ akwa akwa seramiiki

Nnukwu mkpuchi ceramic dayameta na-abụkarị nsogbu buru ibu maka ndị na-emepụta tube seramiiki ebe ọ bụ na ọ na-esiri ike ịchịkwa ọnụego nrụrụ nke seramiiki aka mgbe ọ na-agbanye ya. ga-ọ bụghị nanị na-egosipụta ụlọ ọrụ mmepụta ike, ma ụlọ ọrụ nkà na ụzụ.Ugbu a, ụlọ ọrụ anyị nwere ma uru nke na-eyi ihe na-eguzogide ọgwụ seramiiki na teknụzụ.

Anyị zutere ụfọdụ ihe isi ike n'ezie mgbe anyị na-emepụta ihe mkpuchi seramiiki na anyị na-edozi nsogbu niile mgbe mgbalị nke nyocha anyị na ndị injinia .Ọzọkwa anyị mepụtara igwe nrụnye dị mfe iji mee ihe ntinye aka nke seramiiki n'ime ọkpọkọ ebe ọ bụ na aka uwe dị nnọọ ukwuu. nnukwu na arọ .Mgbe otu ọnwa na-arụ ọrụ, anyị okokụre a 20' akpa 95% alumina seramiiki aka uwe lined ọkpọkọ, T ọkpọkọ na elbows na ndị ahịa na-nnọọ ekele banyere anyị ngwa ngwa mmeghachi omume na nnukwu mgbalị a oru etinyere na Ngwuputa slurry ebu usoro. .

Sintering dị ka a dum seramiiki tube ma ọ bụ seramiiki aka uwe, wee kpọkọta ya n'ime ígwè anwụrụ ma ọ bụ igwe anaghị agba nchara ọkpọkọ na anyị elu-ike-okpomọkụ na-eguzogide epoxy nrapado.The seramiiki aka uwe lined ọkpọkọ etinyere ọtụtụ ihe na Ngwuputa ụlọ ọrụ, dị ka Ngwuputa slurry ọkpọkọ, Ngwuputa ájá wepụ ọkpọkọ, Ngwuputa slag ebu ọkpọkọ, elbows na T ọkpọkọ.

Ụdị ọkpọkọ seramiiki nke a na-etinye n'ime ya nwere akụkụ atọ (steel pipe + nrapado + seramiiki taịlị), a na-eji ọkpọkọ carbon na-enweghị ntụpọ.Akpụkpọ anụ seramiiki bụ 95% elu alumina, na njikọta bụ ihe mkpuchi epoxy dị elu ruo 350oC. Ụdị ọkpọkọ a dị mma maka njem ntụ ntụ na-enweghị tile na-adapụ ma ọ bụ ịka nká na-arụ ọrụ n'okpuru 350oC ruo ogologo oge.Ogologo ndụ ọrụ bụ oge 4 ruo 5 karịa ọkpọkọ ígwè nkịtị.

Ihe nrụnye ọkpọkọ ejiri aka seramiiki kpuchie ngwa ngwa

Ndị ọkpọkọ ndị a na-eji maka Pneumatic na Hydraulic Systems na-ata ahụhụ site na akwa akwa, akwa akwa na mmetụta dị elu, karịsịa maka ikpere ụkwụ.Anyị nwekwara ike ịmepụta ọkpọkọ ọkpọkọ omenala iji zute ngwa ọrụ dị iche iche.

Ihe Tile Wear Ceramic & Foto

-92% Alumina

-95% aluminom

-99% Alumina

-RBSiC Silicon carbide

- ZTA usoro

| Otu | HC92 | HC95 | HCT95 | HC99 | HC-ZTA |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% |

| ZrO2 | / | / | / | / | ≥21% |

| Njupụta (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 |

| HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 |

| Nkume Hardness HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 |

| Ehulata Ike MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 |

| Ike mkpakọ MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 |

| Ike mgbajiji (KIc MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 |

| Yiri olu (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 |