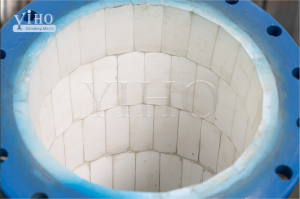

Ọkụ na-eri nri seramiiki Lined Wye

Wyes na ọkpọkọ ọkpọkọ

Wyes ọkpọkọ yiri ọkpọkọ ọkpọkọ.Naanị ihe dị iche bụ na ahịrị alaka ahụ na-agbado n'akuku iji belata esemokwu nke nwere ike igbochi ọsọ ahụ.Njikọ ọkpọkọ na-abụkarị n'ogo ogo 45 karịa ogo ogo 90 na-emebu.Ọ bụrụ na alaka ụlọ ọrụ na-atụgharị na njedebe na-adabere na ahịrị site na ahịrị, ọkpọkọ ọkpọkọ na-aghọ "tee wye".

Isi ihe nke seramiiki

| Otu | HC92 | HC95 | HCT95 |

| Al2O3 | ≥92% | ≥95% | ≥95% |

| ZrO2 | / | / | / |

| Njupụta | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥3.70g/cm3 |

| Mmiri Absorption | ≤0.1% | ≤0.1% | ≤0.1% |

| HV 20 | ≥950 | ≥1000 | ≥1100 |

| Nkume Hardness HRA | ≥82 | ≥85 | ≥88 |

| Ehulata Ike MPa | ≥220 | ≥250 | ≥300 |

| Ike mkpakọ MPa | ≥1050 | ≥1300 | ≥1600 |

| Njiji siri ike Kic MPam 1/2 | ≥3.7 | ≥3.8 | ≥4.0 |

| Yiri olu | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 |

Njirimara seramiiki mejupụtara ọkpọkọ

Ezigbo mgbochi iyi

Ọkpụkpụ ihe mejupụtara seramiiki n'ihi seramiiki corundum (a-AL2O3), ike Mohs nke 9.0 bụ ihe karịrị HRC90.Ya mere, ọ nwere nnukwu iyi na-eguzogide maka mgbasa ozi abrasive nke ụlọ ọrụ dị ka metallurgy, ọkụ eletrik, Ngwuputa, na kol.Arụ ọrụ ụlọ ọrụ ekwenyela na ndụ ike ya dị okpukpu iri ma ọ bụ ọbụna ugboro iri karịa nke ígwè siri ike.

Obere nguzogide ọrụ

SHS seramiiki mejupụtara ọkpọkọ adịghị ka convex spiral ahịrị n'elu ime nke ọkpọkọ nchara na-enweghị nkebi n'ihi na elu ime ya na-adị ire ụtọ, ọ dịghịkwa emebi emebi.A nwalere ịdị nro dị n'ime na njirimara mgbochi mmiri doro anya nke nkeji ule dị mkpa.Ịdị nro nke elu dị n'ime dị mma karịa nke ọkpọkọ ígwè ọ bụla.Ọnụ ọgụgụ drag doro anya bụ 0.0193, nke dị ntakịrị ala karịa ọkpọkọ enweghị nkebi.Ya mere, tube nwere àgwà nke obere nkwụsị na-agba ọsọ ma nwee ike ibelata ụgwọ ọrụ.

Corrosion, mgbochi mkpali

Ebe ọ bụ na oyi akwa seramiiki ígwè bụ (a-AL2O3), ọ bụ àgwà na-anọpụ iche.Ya mere, ọ na-eguzogide acid na alkali na mmiri mmiri corrosion, na ọ nwekwara mgbochi-scaling Njirimara.

Okpomọkụ na-eguzogide na okpomọkụ

N'ihi seramiiki corundum (a-AL2O3), ọ bụ otu usoro kristal kwụsiri ike.Ya mere, ọkpọkọ ngwakọta nwere ike ịrụ ọrụ nke ọma na ogologo oge okpomọkụ nke -50--700 ° C.Ọnụọgụ mgbasawanye ahịrị ihe nke 6-8 × 10-6/0C, ihe dịka 1/2 nke ọkpọkọ ígwè.Ihe onwunwe nwere ezigbo nkwụsi ike okpomọkụ.

Ọnụ ego nke ọrụ ahụ dị ala

Ọkpụkpụ ihe mejupụtara seramiiki dị arọ ma dịkwa ọnụ ala.Ọ dị 50% ọkụ karịa tube nkume nkedo nke nwere otu dayameta dị n'ime;ọ bụ 20-30% dị ọkụ karịa tube alloy na-eguzogide iyi, ọ na-enwekwa ezigbo mgbochi na-eguzogide ọgwụ na corrosion n'ihi ogologo ndụ ọrụ ya, si otú a na-akwado ụgwọ hanger, ụgwọ njem, ụgwọ ntinye, na Belata ụgwọ ọrụ.N'ịtụle mmefu ego oru ngo nke ụlọ ọrụ mmepụta ihe na ụlọ ọrụ na-arụ ọrụ n'ezie, ụgwọ ọrụ a na-akwụ ụgwọ na nkume nkedo.E jiri ya tụnyere ọkpọkọ alloy na-eguzogide iyi, ụgwọ ọrụ a na-ebelata ihe dịka 20%.

Mfe ntinye na iwu ụlọ

N'ihi ịdị arọ ya dị mfe yana ịrụ ọrụ ịgbado ọkụ dị mma.Ya mere, ịgbado ọkụ, flanges, ngwa ngwa njikọ, wdg nwere ike nakweere, na-ewu na echichi bụ adaba, na echichi na-eri nwere ike ibelata.

Ngwa

Ceramic lined anwụrụ elbows nwekwara ike tinye n'ime akụkụ nke ihe mgbapụta n'ihi uru ha, karịsịa obere arọ, nke na-enyere aka zere jam n'oge iga nke ihe.

Dochie ọkpọkọ ígwè carbon, igwe anaghị agba nchara na SDR

Mwepu ihe eji akwa akwa

Nri magnetite na ahịrị igbapu

Tailing eruba